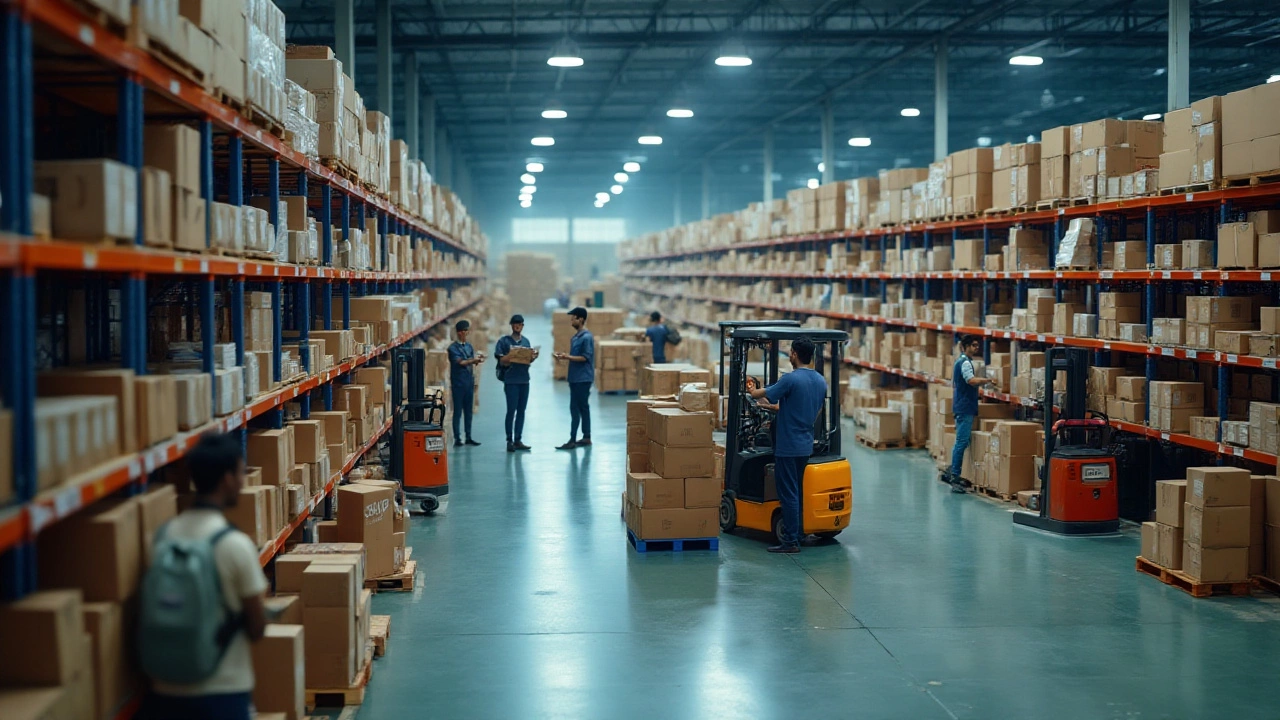

Warehouse Solutions That Keep Your Bikes Safe and Your Business Moving

If you ship motorcycles in Chennai, you already know that a good warehouse is more than just a big empty space. It’s a place where bikes are protected, paperwork is handled, and deliveries happen on time. The right warehouse solution saves you headaches, cuts costs, and makes customers happy. Below you’ll find easy steps to upgrade your storage game without breaking the bank.

Why Modern Warehouses Need Smart Solutions

Old‑school warehouses often rely on manual lists, narrow aisles, and guesswork. That leads to misplaced bikes, wasted labor, and delayed shipments. Smart warehouse solutions bring three big benefits:

- Visibility: Real‑time tracking lets you see where each bike is, so you never lose a unit.

- Efficiency: Barcode scanners or simple QR tags speed up loading and unloading.

- Safety: Proper racking and climate control protect paint, electronics, and tires.

Even a small space can feel organized when you use these tools. For example, a local bike shop in Chennai started using inexpensive handheld scanners and cut its loading time by 30%.

How to Choose the Right Warehouse Solution for Your Bike Business

Picking a system isn’t about buying the most expensive software. It’s about matching features to your needs. Ask yourself these questions:

- Do you need real‑time tracking for each motorcycle?

- Is temperature control important for your inventory?

- How many loading docks do you have, and can they handle larger bikes?

- Do you want a simple inventory spreadsheet or a cloud‑based platform?

If you answer yes to tracking but no to climate control, a basic Warehouse Management System (WMS) that integrates with your phone is enough. If you handle high‑value bikes or have seasonal spikes, consider a solution with automated alerts for temperature and humidity.

Don’t forget the human side. Train your staff on any new tool, and keep a short cheat‑sheet on the wall. A quick reminder of scan steps or safety checks makes adoption painless.

Finally, test the solution on a small batch of bikes before rolling it out fully. Measure loading time, error rates, and any damage incidents. If the numbers improve, you’ve found the right fit.

In short, smarter warehouse solutions let you focus on what matters: getting bikes from point A to point B without a scratch. Start with one simple change—like adding QR tags—and watch the whole operation get tighter.