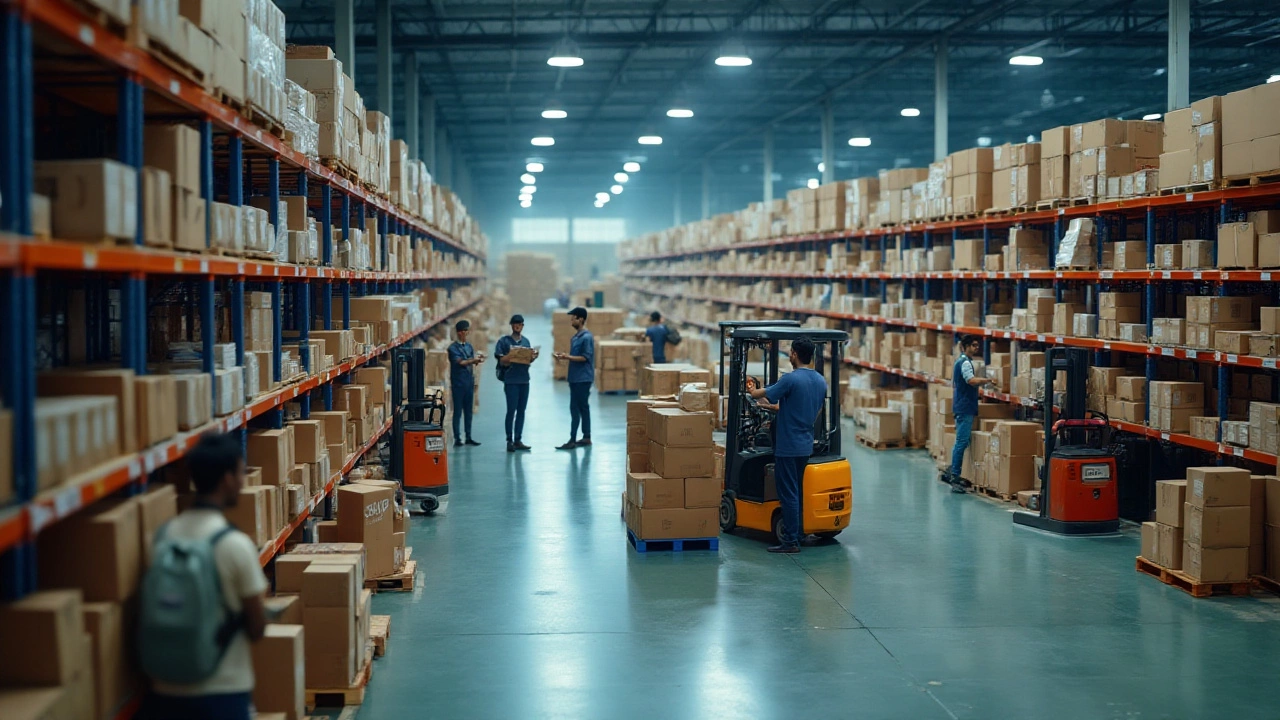

In today's fast-paced business environment, efficiency is the lifeblood of any successful warehouse operation. Whether you're managing a small local distribution center or a sprawling international storage complex, understanding what a Warehouse Management System (WMS) is and what it offers can make or break your logistics game.

A WMS is more than just a tool for keeping track of inventory. It's a dynamic solution that integrates technology into the very fabric of supply chain operations, enhancing accuracy, speeding up processes, and reducing costs. From managing stock locations to streamlining order fulfillment, a good WMS can transform how businesses handle their logistical challenges.

If you're ready to tap into the power of a WMS, or if you're simply curious about the inner workings of these systems, this article will guide you through the essentials. Let's explore how these systems optimize warehouse operations and boost productivity like never before.

- Defining Warehouse Management System

- Benefits of Implementing WMS

- Key Features to Look for in a WMS

- Tips for Choosing the Right WMS

Defining Warehouse Management System

The world of logistics is a complex one, teeming with nuanced operations that require precision and exactness. At the heart of a well-oiled logistics machine is the Warehouse Management System (WMS). But just what is a Warehouse Management System? In the simplest terms, a WMS is an integrated software suite that provides tools to improve the efficiency of the warehouse's day-to-day operations. It tracks the inventory moving in and out of the warehouse, optimizes picking and shipping tasks, and can often be integrated with other systems like Enterprise Resource Planning (ERP) to synchronize across the entire supply chain spectrum.

Having emerged from the digital evolution of logistics management, the Warehouse Management System has transcended its humble beginnings as a simple database of records. Today, it stands as a cornerstone of modern warehousing, offering features like real-time data tracking, analytics, and user-friendly dashboards that encourage efficiency and informed decision-making. In many cases, a WMS employs sophisticated algorithms to ensure optimal stock placement within a warehouse, which in turn helps reduce travel time for order pickers and maximizes storage space.

A notable mention comes from a study by Logistics Management magazine which highlights that businesses using a sophisticated WMS can see improvements in order accuracy by up to 30-40%, effectively reducing errors and boosting customer satisfaction. That's the power of an effective WMS — it not only saves time but also elevates the precision of fulfillment processes. As Scott Luton, a recognized authority in supply chain commentary, once stated,

"A top-tier Warehouse Management System is vitality injected into the life cycle of logistics, turning chaos into cadence."

At its core, a WMS functions as the operational backbone of modern warehouses. It helps maintain an organized flow of goods by regulating everything from how items are received, stored, and eventually sent out for shipping. With demand for efficiency scaling new heights in response to e-commerce growth habits, the deployment of a robust WMS is no longer an option but a necessary strategic asset. Implementing such systems allows warehouses to learn from data patterns, optimizing paths through the facility and leveraging historical trends to predict future needs. For those teetering on the competitive edge, the insights provided by a WMS may be the deciding factor in securing both profitability and customer loyalty.

Benefits of Implementing WMS

The integration of a Warehouse Management System (WMS) into your operations significantly elevates a business's ability to manage inventory efficiently. One of the most acclaimed advantages is the substantial improvement in inventory accuracy. Businesses can attain near-perfect stock accuracy, an invaluable feature which reduces errors and ensures that stockouts and overstock situations are nearly eliminated. This directly translates to improved customer satisfaction as orders are reliably filled and delivered on time.

Another major benefit is the enhancement of operational efficiency. A well-implemented WMS automates various warehouse processes that would otherwise be cumbersome and time-consuming. Take, for instance, the process of picking goods. A WMS optimizes picking routes, reducing the time and effort warehouse employees spend locating and retrieving items. This efficiency boost not only speeds up order fulfillment but also helps in better utilization of warehouse space, leading to cost savings. Businesses often see a marked reduction in their manual labor cost once a WMS is in place.

Cost reduction doesn’t stop at labor. Implementing a WMS helps lower the cost associated with excessive inventory and the mismanagement of warehouse resources. Moreover, with the data-rich reporting capabilities typical of these systems, businesses can engage in more strategic planning and demand forecasting. This shift from reactive to proactive management strategies allows warehouses to gauge future needs more accurately, making operations leaner and more responsive to market shifts. The impact is a seamless juggling act of supply and demand that enhances profitability.

Many successful brands advocate for warehouse management systems because they enhance customer and supplier relations exponentially. With improved inventory transparency and communication, businesses can establish stronger, more reliable connections with their stakeholders. Richard Branson once said,

"Take care of your employees, and they’ll take care of your business."Although this focuses on employees, similar principles apply to managing logistics networks, where proper systems nurture reciprocal value appreciation.

The benefits extend to better regulatory compliance, an often underestimated facet of warehouse management. With a WMS, maintaining records and ensuring adherence to industry regulations become significantly easier. Proper documentation and audit trails ensure smoother operations, avoiding potential legal and financial penalties. As an integrated solution, a WMS turns the complex matrix of warehouse activity into an organized symphony of movement, not only meeting legal requirements but ensuring that those obligations are addressed as part of routine business operations.

| Highlighted WMS Benefits | |

|---|---|

| Improved Accuracy | Reduces inventory errors |

| Efficiency Boost | Optimizes picking routes |

| Cost Savings | Decreases labor and inventory costs |

| Strategic Planning | Improves demand forecasting |

| Compliance Ease | Enhances regulatory adherence |

With all these benefits, it's evident why adopting a Warehouse Management System can serve as a game-changer for businesses looking to stay competitive in the logistics landscape. It enables more than just inventory management; it orchestrates a harmonious workflow that underpins business growth and efficiency.

Key Features to Look for in a WMS

When exploring the essential components of a Warehouse Management System, several features stand out as integral to creating a smooth-running warehouse operation. One of the foremost capabilities to seek is real-time inventory visibility. This feature offers a comprehensive view of stock levels, so warehouse managers can make informed decisions, reduce overstock, and quickly identify trends. Without a doubt, it's an indispensable function that helps keep workflows seamless and operations efficient.

Another critical feature to incorporate is advanced order fulfillment abilities. An effective WMS should support diverse order processing methods while adapting to various shipping requirements. This includes handling multiple pick-and-pack strategies and facilitating rapid order cycle times. By having a system with these capabilities, your inventory control becomes more manageable, and your warehouse can turn challenges into opportunities, leading to cost savings and elevated customer satisfaction.

In addition to core functionalities, scalability and flexibility are key considerations. A WMS should grow with your business needs, adapting to changes in volume and complexity. Integration capabilities with other software, like ERP systems, add another layer of flexibility. As technologies evolve, enabling seamless connections between warehousing solutions and other enterprise software can have a dramatic impact on productivity. An integrated system reduces errors and ensures data consistency across various platforms, propelling your warehouse solutions to new heights.

According to supply chain experts, automation is an indispensable feature that saves time and minimizes human error. As warehouses face increasing demands, automated processes such as barcode scanning, RFID integration, and automated guided vehicles (AGVs) become invaluable. These technologies streamline operational workflows and bolster speed without sacrificing accuracy. A respected journal notes,

"Automating routine tasks in a WMS allow employees to focus on value-added activities, leading to a more agile and responsive warehouse."

Lastly, prioritizing user-friendly interfaces and comprehensive reporting tools ensures effective team collaboration and insights into operations. An intuitive system equates to quicker onboarding and higher engagement. When employees can easily navigate and utilize the management system, it leads to improved efficiency on the warehouse floor. Alongside ease of use, powerful reporting and analytics empower decision-makers to identify inefficiencies and optimize strategies swiftly. With access to detailed reports, tracking key performance indicators becomes simpler, driving success and growth for your warehouse operations.

Tips for Choosing the Right WMS

When venturing into the domain of warehouse solutions, selecting the ideal Warehouse Management System (WMS) is a task that calls for careful consideration and understanding. As businesses evolve, having a robust system for managing inventory is not just a competitive edge, it’s imperative. First off, identify the specific needs of your warehouse. Every facility has unique requirements based on factors like size, type of products, and order volume. Customizing the WMS to align with specific operational nuances can make all the difference. Think about how a system either integrates with existing infrastructure or if it necessitates a total overhaul.

Choosing a WMS that offers high scalability is another vital aspect. Businesses may experience sudden growth spurts, and an inflexible system may lead to operational bottlenecks. A scalable WMS ensures smooth transitions during expansion. As your enterprise grows, the system should gracefully handle added complexities without suffering from performance lags. Always prioritize systems offering periodic updates and improvements that align with the ever-changing landscape of warehouse management solutions.

An essential factor that may sometimes be overlooked is the user experience. A complicated interface can lead to inefficiencies and errors that defeat the purpose of implementing a sophisticated system. Training staff extensively can mitigate this, but opting for a WMS that is intuitive and user-friendly reduces the training time significantly. Consider the system’s capabilities in supporting multilingual operations, especially if you operate on a global scale.

Remember to evaluate the level of support and service offered by the WMS provider. Effective customer support can be a lifeline during critical times. When unexpected technical issues arise, a responsive support team can prevent potential disruptions. According to industry expert Martin Green, "A rapid response from your support team can save you crucial hours of downtime, allowing your team to focus back on what they’re best at." Always check reviews or request references from other clients to gauge the provider's reliability.

Cost, of course, is another pivotal element. While costlier systems may offer a plethora of features that appear tempting, it's crucial to match them with real requirements. Opt for a solution that provides the best return on investment without stretching your budget too thin. Some systems might offer customizable modules, allowing you to purchase only what's necessary at the moment, with the flexibility to add more functionalities as needed.

Finally, consider data security and compliance. In an age where digital threats loom large, ensuring your WMS is equipped with advanced security protocols safeguards sensitive business data. Compliance with industry standards—such as ISO or local regulatory requirements—provides another layer of accountability and protection. Prioritizing these aspects not only protects your business but builds trust with your clients, creating an added advantage. With these tips in mind, you’re well on your way to finding a WMS that not only meets your present needs but also paves the way for future growth.