WMS – Your Quick Guide to Warehouse Management Systems

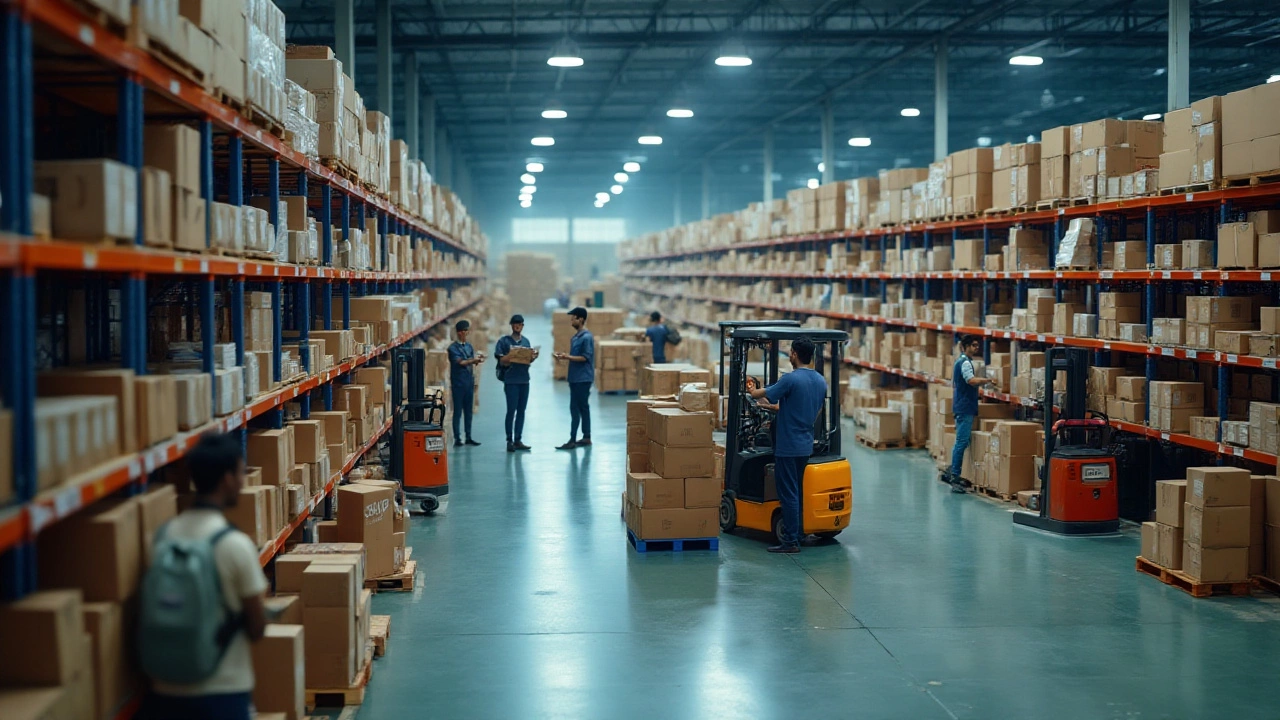

If you run a warehouse, you’ve probably heard the term WMS thrown around a lot. It stands for Warehouse Management System, a software tool that helps you keep track of inventory, orders, and staff activity. Think of it as the brain behind the shelves, making sure the right product gets to the right place at the right time. In this guide we’ll break down what a good WMS looks like and how to pick one that fits your needs.

What Makes a Good WMS?

A solid WMS does three things well: visibility, automation, and scalability. Visibility means you can see every item in real‑time, from the moment it arrives to the moment it leaves. Automation takes repetitive tasks like picking lists or slotting decisions and does them faster than a human could. Scalability ensures the system can grow with your business, whether you add more SKUs, new locations, or higher order volumes.

Look for features such as barcode scanning, real‑time dashboards, and integration with your existing ERP or e‑commerce platform. A user‑friendly interface saves time on training—your staff should be able to click a few buttons, not study a manual for hours. Also check the support options; a responsive help desk can save you money when something goes wrong.

How to Pick the Right WMS for Your Business

Start by listing the problems you need to solve. Do you struggle with inaccurate stock counts, slow picking times, or missed shipments? Match each pain point to a WMS feature. For example, if you lose track of inventory, choose a system with strong cycle‑counting tools and audit trails.

Next, set a realistic budget. WMS pricing can be subscription‑based, per‑user, or based on transaction volume. Get quotes from a few vendors and ask for a demo that uses your own data. A live demo shows how the system handles your specific workflow and reveals any hidden complexities.

Don’t forget to think about implementation time. Some WMS solutions can be up and running in weeks, while others need months of configuration and testing. Ask the vendor about migration support and whether they provide data conversion services.

Finally, read reviews from businesses similar to yours. Look for comments about customer service, system reliability, and how often the software gets updates. A WMS that evolves with technology—adding mobile apps, AI‑driven forecasting, or cloud hosting—will keep you ahead of the competition.

Choosing a WMS is a big decision, but breaking it down into clear steps makes it manageable. Focus on visibility, automation, and scalability, match features to your pain points, and test the system with your own data before you commit. With the right WMS in place, your warehouse can run smoother, faster, and with fewer errors—leaving you more time to grow your business.