Warehouse Management Made Simple: What You Need to Know

If you run a warehouse or help a business with storage, you know every minute counts. A smooth warehouse saves money, keeps customers happy, and stops headaches. Below are the core steps you can start using right now, no matter the size of your operation.

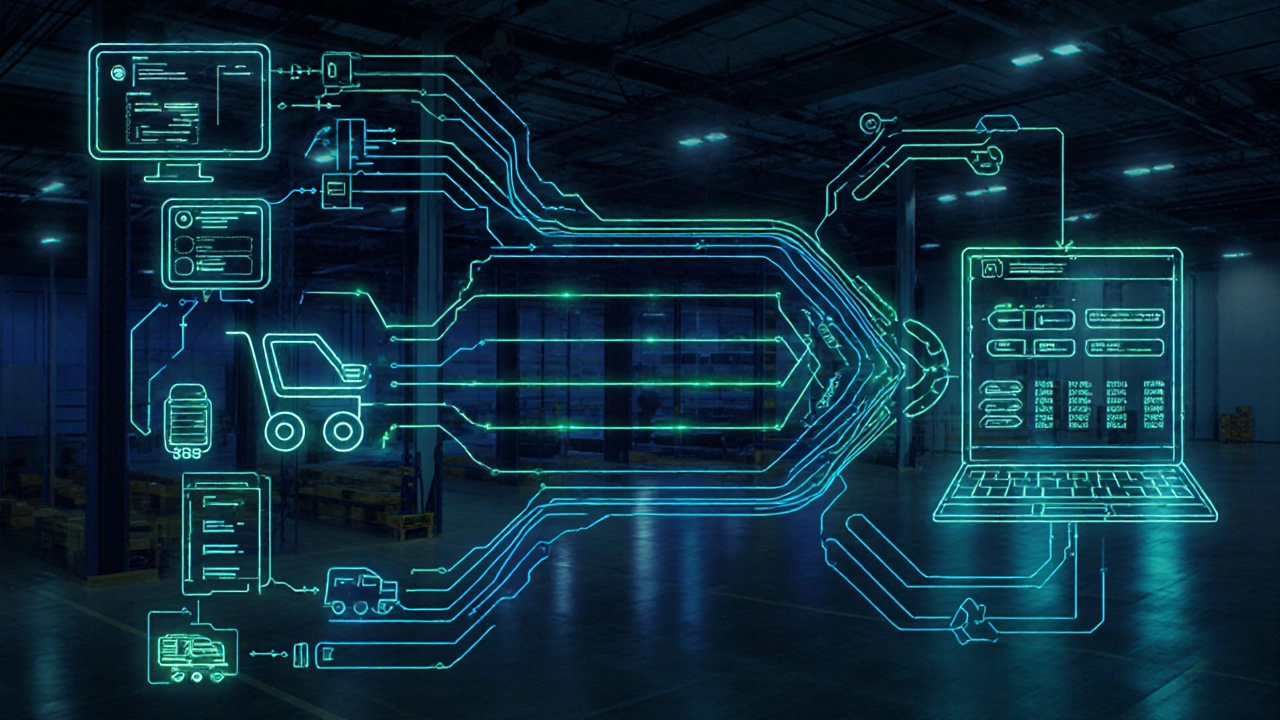

Pick the Right Warehouse Management System (WMS)

The biggest upgrade you can make is a good WMS. Look for software that does three things: tracks inventory in real time, helps you plan picks and puts, and talks to other tools like your shipping system. You don’t need a massive, enterprise‑grade platform if you only handle a few hundred bikes a month – a cloud‑based solution that charges per user can be enough. Test the demo, ask how it handles returns, and make sure the interface feels intuitive. If the staff can learn it in a day, you’re on the right track.

Organize Space for Speed and Safety

Once the tech is set, the layout matters just as much. Start by mapping out high‑turnover items near the loading dock. Put slow‑moving stock on higher shelves or in the back corner. Use clear aisle markings and keep walkways at least three feet wide – it reduces trips and makes forklift routes safer. Label every bin with large, legible numbers; a quick visual cue cuts search time dramatically.

Next, adopt a simple “first‑in, first‑out” (FIFO) rule for most products. This prevents old stock from gathering dust and reduces the chance of selling expired or outdated items. If you have items that need special handling – fragile bike parts, for example – assign them a dedicated zone and use padded pallets.

Finally, train your team on these basics every month. A short refresher on where items live, how to use the WMS, and safety checks keeps everyone on the same page. When people know why a process exists, they’re more likely to follow it.

Putting these three ideas together – a user‑friendly WMS, a smart layout, and regular training – creates a warehouse that moves fast, stays safe, and supports your business growth. Start small, measure results, and tweak as you go. Your next shipment will feel a lot smoother, and you’ll see the savings add up quickly.