E-Commerce Logistics Impact Calculator

Optimize Your Logistics Performance

See how improving key logistics metrics impacts your customer satisfaction and revenue based on industry benchmarks from the article.

Enter Your Current Metrics

Your Potential Improvements

Revenue Impact

$0

Potential monthly revenue increase

Customer Retention

0%

Projected increase in repeat customers

Return Reduction

0%

Potential reduction in return rate

Key Insights from Your Results

Running an online store isn’t just about having a sleek website and good product photos. If your logistics don’t work, customers won’t come back. Every time someone hits "Buy Now," a chain of hidden processes kicks into motion. Miss one step, and you’re dealing with late deliveries, wrong items, angry customers, and returns that eat into your profits.

Order Receiving and Processing

It starts the moment a customer completes their purchase. The order details-product, size, color, shipping address, payment confirmation-must flow instantly from your online store to your warehouse system. If your e-commerce platform doesn’t talk cleanly to your warehouse management software, you’re manually entering orders. That’s a recipe for mistakes. One wrong SKU, one misspelled address, and you’re sending a size 10 shoe to someone who ordered size 7.

Automated order processing cuts errors by up to 70%. Systems like Shopify Plus, BigCommerce, or Magento integrated with tools like ShipStation or Ordoro can auto-route orders based on inventory location, shipping speed, and carrier rates. No human needs to touch it. That’s not luxury-it’s baseline for any store doing more than 50 orders a day.

Inventory Management

Knowing what you have in stock isn’t optional. It’s the core of everything else. If you think you have 200 blue t-shirts but only have 47, you’re going to oversell. And overselling means canceled orders, refunds, and damaged trust.

Real-time inventory tracking uses barcode scanners, RFID tags, and cloud-based systems that update the moment an item is picked, packed, or returned. It’s not enough to just count boxes in the back room. You need to know exactly where each item is-on shelf A3, in quarantine due to damage, or on its way to a fulfillment center in Chicago.

Companies that sync inventory across multiple warehouses (like Amazon does) can ship from the closest location. That cuts delivery time and shipping cost. If you’re selling nationwide, you need multi-location inventory visibility. Otherwise, you’re shipping a hoodie from California to Toronto when you have five in your Toronto warehouse.

Warehouse Management and Picking

Once the order is confirmed, the warehouse has to find the item and get it ready to ship. This sounds simple, but it’s where most small e-commerce businesses break down. Picking is the process of gathering products from storage to fulfill an order. In a messy warehouse, a picker might walk 2 miles a day just to find items. That’s wasted time and labor.

Smart warehouses use wave picking, batch picking, or zone picking to group orders efficiently. For example, if five orders all need the same phone case, the picker grabs 5 at once instead of making five separate trips. Warehouse Management Systems (WMS) like NetSuite or Fishbowl guide pickers with digital lists and optimized routes. Some even use voice-directed picking-workers hear instructions through headsets instead of staring at screens.

Storage layout matters too. Fast-moving items go near the packing station. Slow-movers get pushed to the back. If your best-selling product is buried under boxes of seasonal decor from last year, you’re losing money every hour.

Packing and Labeling

Picking is only half the battle. Packing is where you control the customer’s first physical impression. A poorly packed item arrives damaged. A box that’s too big wastes shipping material and increases cost. A box that’s too small looks unprofessional.

Automated packing stations can recommend the right box size based on item dimensions. They print labels with tracking numbers, customs forms, and carrier barcodes in seconds. Many e-commerce brands now use branded packaging-custom tape, thank-you notes, free samples. It’s not just about protection. It’s about turning a delivery into a moment of delight.

Labeling errors are one of the top causes of lost packages. A wrong carrier code or missing customs declaration can hold a package at the border for weeks. Automated systems reduce labeling errors to under 0.5%. Manual labeling? You’re looking at 5-10% error rates.

Last-Mile Delivery

This is the final leg-the delivery from your local hub to the customer’s door. It’s the most expensive part of logistics, often costing more than the entire rest of the supply chain combined. And it’s the part customers remember the most.

Customers today expect same-day or next-day delivery. If you’re using a single carrier like Canada Post for everything, you’re falling behind. Top e-commerce brands use multi-carrier routing. They send small packages via local couriers like Purolator or FedEx Ground, larger items via LTL freight, and urban deliveries via gig-based services like Uber Connect or local bike couriers in Toronto.

Real-time tracking is expected. If a customer can’t see where their package is, they’ll call. Or worse-they’ll leave a bad review. Delivery apps that show live maps, estimated arrival windows, and digital signatures are now standard. Some even let customers reschedule delivery or choose drop-off locations like lockers or neighbors’ porches.

Returns and Reverse Logistics

One in every three online orders gets returned. That’s not failure-it’s normal. But how you handle returns determines whether the customer comes back.

Many small businesses treat returns as a cost center. Smart ones treat them as a process. A clear return policy, pre-paid labels, and drop-off points at local stores (like Walmart or Canada Post) make returns easy. Automated return portals let customers print labels, track their return, and get refunds instantly.

Reverse logistics isn’t just about getting the item back. It’s about deciding what to do with it. Can it be resold as new? Does it need repair? Is it damaged beyond use? Each path has a different cost. Sorting returns quickly cuts losses and gets items back into inventory faster.

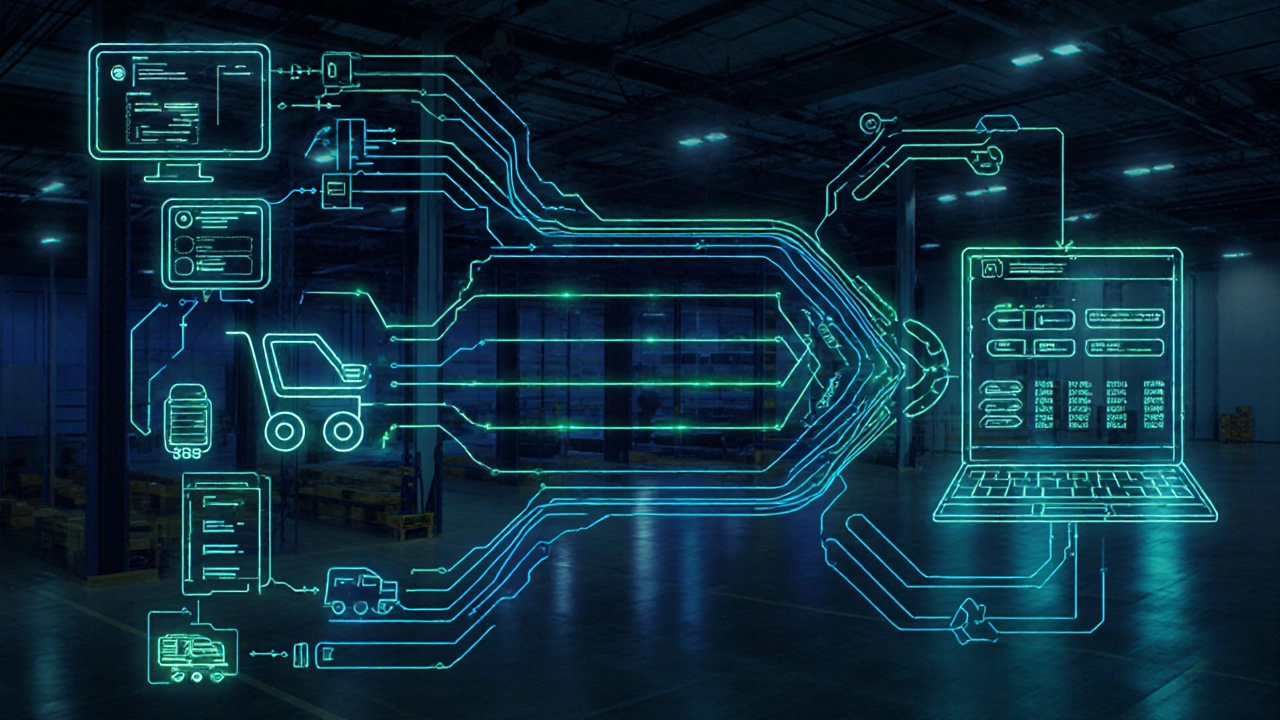

Technology Integration

All these processes-order receiving, inventory tracking, picking, packing, shipping, returns-need to talk to each other. If you’re using Excel for inventory, Shopify for sales, and a separate app for shipping labels, you’re running on duct tape and hope.

Integration is the silent hero of e-commerce logistics. Platforms like Unicommerce, Cin7, or Skubana connect your store, warehouse, carrier, and accounting systems. Data flows automatically. You don’t have to retype anything. Errors drop. Speed increases. Costs shrink.

You don’t need a $100,000 system. Even small stores can start with Shopify + ShipStation + Google Sheets for inventory. The key is making sure the systems speak the same language. Otherwise, you’re just adding more work.

Why This Matters

Logistics isn’t the glamorous side of e-commerce. No one posts a TikTok about pallets being loaded onto trucks. But it’s what makes the whole thing work. A customer doesn’t care how many ads you ran. They care if their order arrived on time, in good condition, and with a smile.

Companies that nail these seven processes see 30-50% lower return rates, 25% faster delivery times, and 20% higher repeat purchase rates. It’s not magic. It’s systems. It’s discipline. It’s knowing that behind every click is a real person waiting for something they bought.

Start by mapping out your current process. Where are the delays? Where do mistakes happen? Fix one thing at a time. Automate the repetitive stuff. Track your metrics-on-time delivery rate, order accuracy, return rate. Then improve. That’s how you turn logistics from a cost center into your biggest competitive advantage.

What’s the most important process in e-commerce logistics?

There’s no single most important process-it’s the chain that matters. But if one step fails, the whole thing breaks. Order accuracy and last-mile delivery have the biggest impact on customer satisfaction. If you get the item wrong or it’s late, the customer won’t care how fast your warehouse picked it. Focus on reducing errors and meeting delivery promises.

Can I handle e-commerce logistics myself without software?

You can, but only if you’re doing under 20 orders a week. Once you hit 30-50 orders, manual tracking becomes overwhelming. You’ll start missing shipments, sending wrong items, or losing packages. Software doesn’t replace you-it frees you up to focus on customer service and growth. Start with free tools like Google Sheets for inventory and ShipStation’s free tier for labels.

How do I reduce shipping costs in e-commerce?

Use multi-carrier shipping software that compares rates in real time. Negotiate volume discounts with carriers once you’re shipping over 500 packages a month. Ship from locations closest to your customers. Use smaller, lighter packaging. And offer slower shipping options-many customers will choose free 5-day delivery over paid 2-day if the price difference is big enough.

What’s the biggest mistake new e-commerce sellers make with logistics?

They assume logistics is just about shipping. It’s not. It’s inventory, picking, packing, returns, and tech integration. Many sellers order too much stock upfront, then can’t track it. Or they use one carrier for everything, even when it’s slow or expensive. The fix? Start small. Track your numbers. Improve one step at a time.

Do I need a warehouse to sell online?

No. You can use dropshipping, third-party fulfillment centers (like Amazon FBA or ShipBob), or even store inventory at home. But if you’re selling more than 100 items a month, a dedicated warehouse space or fulfillment partner saves time and reduces errors. Home storage works for starters, but it doesn’t scale. Think of your warehouse as your operational backbone.