Warehouse Management System: What It Is and Why You Need It

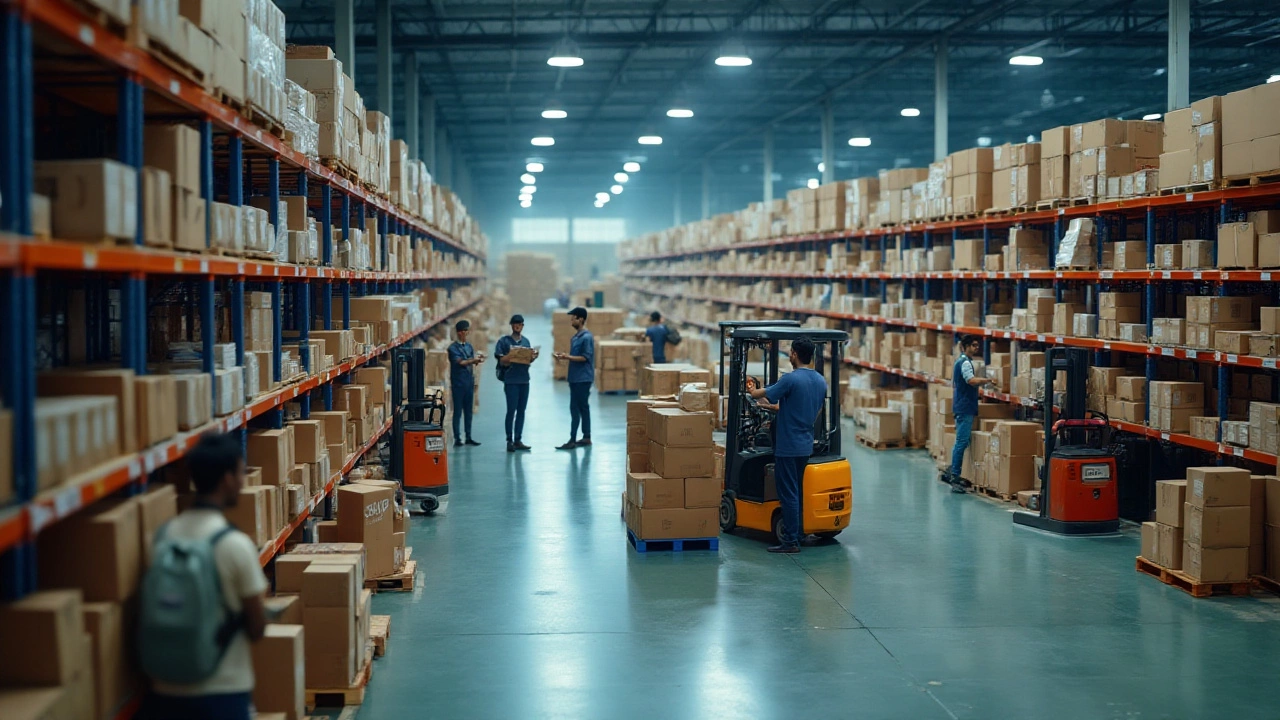

Ever felt the chaos of a packed warehouse – misplaced items, missed shipments, and endless paperwork? A Warehouse Management System (WMS) is the digital tool that turns that mess into a smooth, trackable flow. It’s basically software that tells you where every box, pallet, or bike is at any moment, and helps you move it efficiently.

Think of a WMS as a traffic controller for your storage space. It guides inbound trucks, directs where items should be stored, and plans the best route for pickers to grab the right product. The result? Faster orders, fewer mistakes, and happier customers.

Key Features to Look For

Not all WMS solutions are built the same. Here are the must‑have features that separate a good system from a great one:

- Real‑time inventory tracking: See exact stock levels the second a product moves.

- Slotting optimization: The software suggests the best spot for each item based on size, demand, and turnover.

- Barcode & RFID support: Scanning replaces manual entry, cutting errors dramatically.

- Integration with other tools: Talk to your ERP, e‑commerce platform, or transportation management system without extra hassle.

- Reporting & analytics: Get dashboards that show order cycle time, picking efficiency, and cost per move.

If you’re in a bike‑transport business, look for a WMS that can handle oversized items, schedule loading bays, and flag any special handling instructions.

How a WMS Improves Your Business

First, it slashes the time needed to locate stock. Instead of walking aisles looking for a missing bike part, you get an instant map on your tablet showing the exact bin. That alone can cut pick time by 20‑30%.

Second, it reduces errors. When a worker scans a barcode, the system confirms the SKU and quantity before the item leaves the dock, preventing costly wrong‑shipments.

Third, it boosts space utilization. By recommending tighter slotting and stacking rules, a WMS can increase usable storage by up to 15%, meaning you need fewer rentals or can store more bikes in the same footprint.

Fourth, you gain better visibility into costs. The analytics tell you which products sit idle, which routes waste fuel, and where labor is over‑ or under‑used. Armed with that data, you can renegotiate carrier rates or re‑train staff for better productivity.

Lastly, a modern WMS often comes with mobile apps. Your floor staff can receive pick lists, confirm shipments, and report issues on the go, keeping the whole operation connected.

Implementing a WMS doesn’t have to be a massive overhaul. Many providers offer cloud‑based, pay‑as‑you‑go plans that let you start with core inventory tracking and add advanced features later. That flexibility is perfect for small to midsize warehouses looking to grow without huge upfront costs.

Bottom line: a Warehouse Management System is the backbone of an efficient, error‑free warehouse. Whether you’re moving bikes across Chennai or shipping e‑commerce orders nationwide, the right WMS will keep your stock where it belongs, your orders on time, and your bottom line healthy.