What Is the Average Warehouse Rent in the US? 2025 Guide

Discover the 2025 average US warehouse rent, regional price differences, key cost drivers, and tips for securing the best lease.

When working with US warehouse leasing, the process of renting storage space for goods inside the United States. Also known as industrial space rental, it lets businesses secure a physical hub without buying property. Effective Warehouse Management System, software that tracks inventory, orders, and movements within a warehouse is a core tool for anyone leasing space, because real‑time data drives better space utilization. Logistics Management, the coordination of transportation, inventory, and order fulfillment activities ties directly to lease decisions – a poorly located lease can cripple your delivery speed. Freight Forwarding, the service that arranges the movement of goods across borders and modes often relies on flexible warehouse contracts to adapt to volume spikes. Finally, understanding Warehouse Types, such as storage, distribution, and fulfillment centers helps you pick the right lease model for your operation.

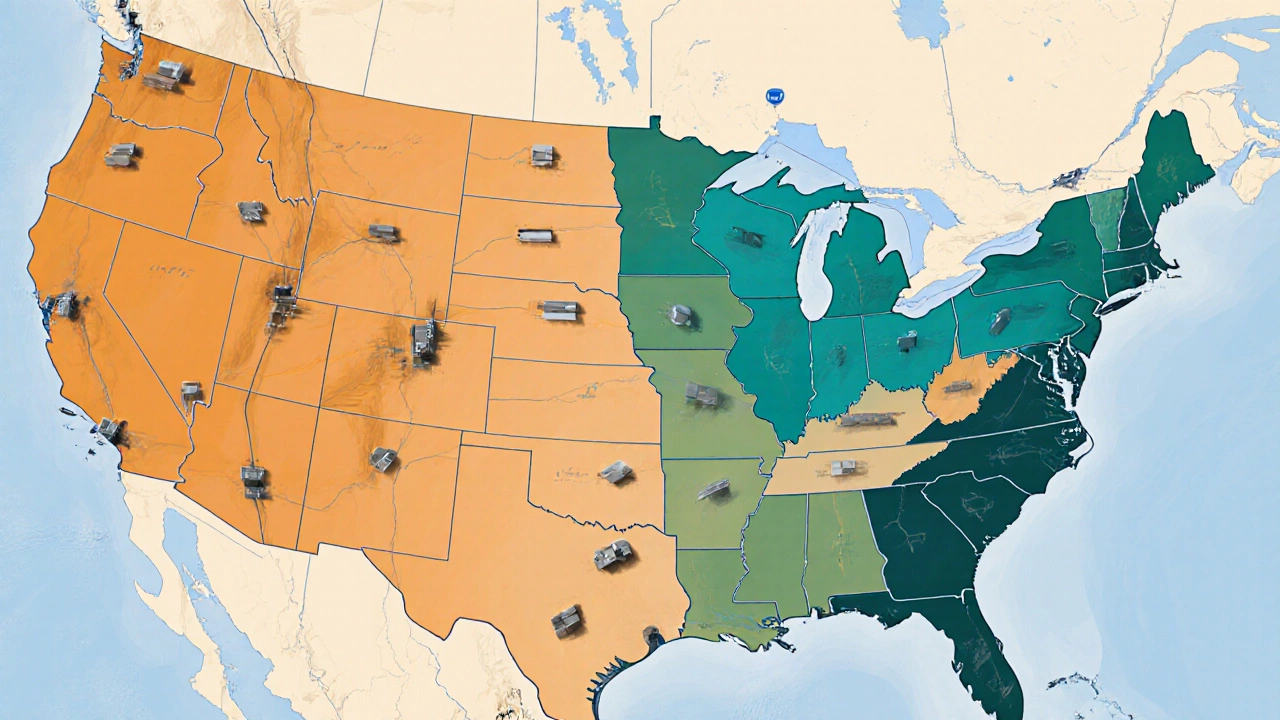

Choosing a lease starts with location analysis – proximity to highways, ports, or key markets reduces transportation costs and improves delivery times. In other words, US warehouse leasing encompasses site selection, rent negotiation, and compliance checks. A lease that sits within a major logistics corridor can shave days off lead times, which directly boosts customer satisfaction. On the flip side, a cheap but remote space may force you to spend more on trucking, eroding any rent savings. This trade‑off is why many firms run cost‑benefit models before signing a contract.

Lease terms themselves are a hot topic. Most agreements run from three to ten years, with options to renew or expand. Early‑termination clauses, build‑out allowances, and shared‑maintenance responsibilities are all negotiable points. For example, a build‑out allowance lets you customize racking, lighting, or climate control to match your inventory needs, while a shared‑maintenance clause can reduce unexpected repair bills. Understanding these details is crucial because they affect both your upfront cash flow and long‑term operational flexibility.

Today’s leases aren’t just about square footage; they’re about data. Integrating a Warehouse Management System with the landlord’s building automation can give you visibility into dock door availability, temperature control, and energy usage. This integration is a key feature of modern Supply Chain Software, platforms that combine WMS, TMS, and ERP functions. When your WMS talks to the building’s IoT sensors, you can automate slotting, reduce idle time, and keep inventory safe. The same logic applies to e‑logistics solutions that route shipments based on real‑time warehouse capacity, boosting efficiency across the network.

Operational considerations also shape lease success. Hiring a skilled warehouse manager who understands safety standards, inventory accuracy, and labor scheduling can make a leased space perform like an owned facility. Insurance requirements, such as general liability and cargo coverage, must be reviewed with the landlord to ensure gaps are covered. Finally, security systems – cameras, access controls, and fire suppression – are often shared responsibilities, so clarify who handles what before you move in.

All these factors – location, lease terms, technology, and operations – create a web of decisions that determine whether a lease fuels growth or becomes a cost sink. In the collection that follows, you’ll find detailed articles about logistics management systems, warehouse automation, freight forwarding basics, and the biggest players shaping the US logistics market. Dive in to get the specific insights you need to negotiate the right lease, set up the right tech stack, and keep your supply chain humming.

Discover the 2025 average US warehouse rent, regional price differences, key cost drivers, and tips for securing the best lease.