Reorder Point Calculator

Calculate Your Optimal Reorder Point

This tool helps you determine the right reorder point to avoid stockouts based on your historical usage patterns and supplier lead times.

When a small warehouse or ecommerce operation asks, "Can Excel track inventory?" the short answer is yes - but you need the right setup. Below you’ll find a step‑by‑step guide that turns a plain spreadsheet into a usable inventory system, plus a realistic look at where Excel falls short and when a dedicated logistics platform is worth the investment.

Why inventory tracking matters for any logistics operation

Accurate stock counts prevent stock‑outs, reduce holding costs, and keep order‑fulfillment timelines reliable. In a fast‑moving fulfillment center, a missed SKU can mean a delayed shipment, a dissatisfied customer, and lost revenue. Even a modest operation benefits from real‑time visibility, safety‑stock calculations, and clear audit trails - all of which can be captured in a well‑designed spreadsheet.

Turning a spreadsheet into an inventory ledger

The first step is to create a table that captures the essential data points for each SKU. A basic layout includes:

- Item ID / SKU

- Product name

- Category

- Location (aisle, bin)

- Quantity on hand

- Reorder point

- Unit cost

- Supplier

In Microsoft Excel a spreadsheet program from Microsoft Office widely used for data analysis and reporting, turn this range into an official Table (Insert → Table). Tables automatically expand as you add rows and make formula references easier to read.

Key Excel features that make inventory tracking doable

Below are the most useful built‑in tools:

- Data Validation lets you create drop‑down lists for categories, locations, or suppliers, reducing entry errors.

- Conditional Formatting highlights low‑stock items in red when quantity falls below the reorder point.

- Formulas SUM, SUMIF, and VLOOKUP calculate total stock, value, and supplier‑wise summaries.

- PivotTable summarizes inventory by category, location, or supplier with a few clicks - perfect for quick management reports.

- Power Query imports data from external sources (CSV export from barcode scanners, ERP reports) and cleans it before it lands in your master sheet.

- VBA macros automate repetitive tasks such as stock adjustments, low‑stock email alerts, or bulk uploads.

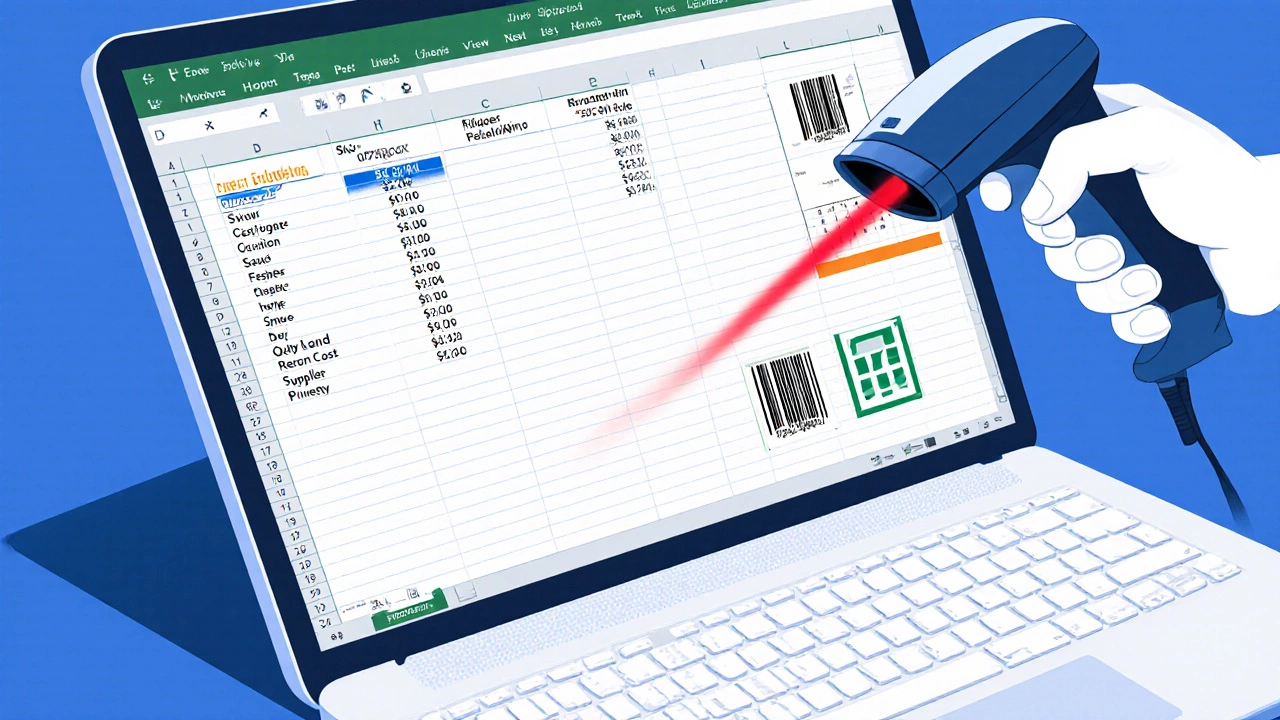

Getting barcode scanning to work in Excel

Most handheld scanners act as keyboard input. Set the SKU column to text format, then scan items directly into the sheet. Pair scanning with a simple VBA macro that adds the scanned quantity to the existing stock level:

Sub AddScannedQty()

Dim sku As String, qty As Long

sku = InputBox("Scan SKU")

qty = InputBox("Enter quantity")

With Sheets("Inventory")

Dim r As Range

Set r = .Columns("A").Find(sku, LookIn:=xlValues)

If Not r Is Nothing Then

r.Offset(0, 4).Value = r.Offset(0, 4).Value + qty

End If

End With

End Sub

The macro can be assigned to a button on the worksheet, turning a manual entry process into a one‑click operation.

Storing and sharing your file safely

Excel files saved to OneDrive Microsoft’s cloud storage service that enables real‑time collaboration on Office documents let multiple team members view or edit the inventory ledger simultaneously. Permissions can be restricted to read‑only for auditors while giving managers full edit rights.

Combine OneDrive with the mobile Excel app, and you can update stock counts directly from a tablet on the warehouse floor. The same file can be linked to Power BI for visual dashboards, but that step is optional for small teams.

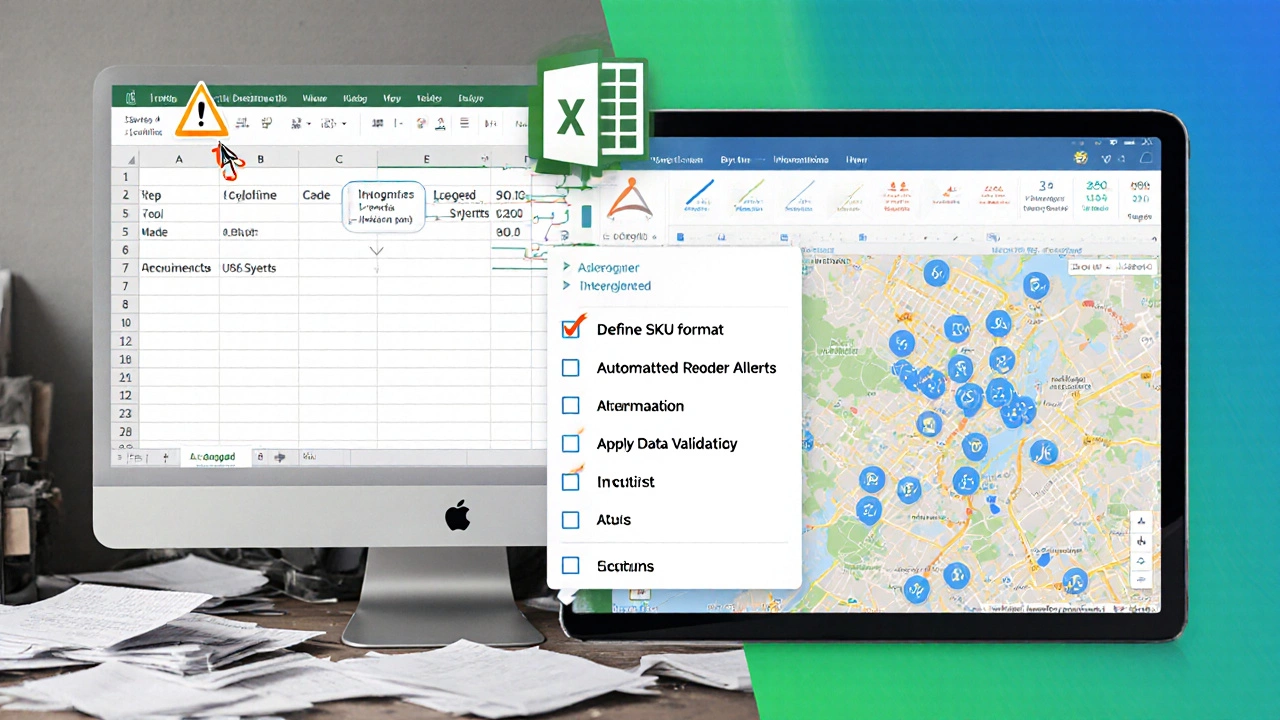

When Excel is not enough - warning signs

Excel shines for low‑to‑mid volume operations, but there are clear limits:

- Concurrent users >5 start to cause edit conflicts.

- Complex multi‑warehouse networks need automated location tracking that spreadsheets can’t provide.

- Regulatory compliance (e.g., traceability for food or pharmaceuticals) often requires audit trails beyond Excel’s version history.

- Scalability - tables over 50,000 rows become sluggish, and formulas recalculate slowly.

If you hit any of these roadblocks, it’s time to evaluate a dedicated inventory system.

Excel vs. dedicated inventory software - a quick comparison

| Feature | Excel (with VBA/Power Query) | Fishbowl Inventory | Zoho Inventory |

|---|---|---|---|

| Real‑time multi‑user editing | Limited - edit conflicts possible | Yes - cloud‑based concurrency | Yes - built‑in collaboration |

| Barcode & RFID integration | Manual via keyboard emulation | Native scanner support, RFID | Native scanner support |

| Automated reorder alerts | Conditional formatting + VBA email | Automated triggers & purchase orders | Automated alerts & supplier portals |

| Reporting & dashboards | PivotTables, Power BI optional | Built‑in analytics, real‑time KPI | Customizable reports, dashboards |

| Cost (per user) | License already owned (Office 365) | ~$4,395 one‑time + support | $79‑$199 per month |

| Scalability (records) | ~50,000 rows before lag | Millions of SKUs, multi‑warehouse | Millions, cloud‑native |

Use the table to decide whether your current volume and process complexity justify the extra spend.

Checklist - building a reliable Excel inventory system

- Define a consistent SKU format (e.g., CAT‑001‑SIZE).

- Create a Table with the core columns listed above.

- Apply Data Validation for Category, Location, and Supplier.

- Set Conditional Formatting to flag quantities below the reorder point.

- Build a PivotTable dashboard that shows total stock, value, and low‑stock items.

- Use Power Query to import daily scanner exports and append them to the master table.

- Write a simple VBA macro to automate stock‑in and stock‑out operations.

- Store the workbook on OneDrive and grant edit rights only to inventory managers.

- Schedule a weekly backup (export to CSV) for audit purposes.

Follow these steps and you’ll have a functional, low‑cost inventory tracker that supports everyday logistics needs.

Next steps and troubleshooting

If you notice slow recalculations, consider splitting the data into separate workbooks (one per warehouse) and linking them with Power Query. For frequent edit conflicts, switch to the shared‑online version of Excel and lock specific cells using sheet protection. When you’re ready to upgrade, look for platforms that offer a free trial and can import your existing Excel file directly - most modern tools support CSV import.

Frequently Asked Questions

Can I use Excel for multi‑warehouse inventory?

Yes, but you’ll need a separate sheet for each warehouse and a master summary that pulls data via formulas or Power Query. Performance will degrade as the number of rows grows, so monitor file size.

How do I prevent accidental deletions?

Use sheet protection (Review → Protect Sheet) and lock critical columns. Pair that with version history on OneDrive so you can restore a previous state.

Is barcode scanning really worth the effort?

For operations handling dozens of SKUs a day, manual entry may be fine. Once you hit hundreds of movements daily, a scanner cuts entry time by 70‑80% and reduces typos dramatically.

Can I automate low‑stock emails with Excel?

Yes. A simple VBA routine can loop through rows, check the reorder point, and use Outlook automation to send an email to the buyer. There are many free snippets online.

When should I switch to a dedicated inventory system?

If you need real‑time multi‑user editing, automated purchase orders, or compliance‑grade audit trails, the cost of a purpose‑built platform is justified. Use the comparison table above to weigh features against price.