The e-commerce game is brutal. Shoppers expect speed, accuracy, and zero drama when they order. Behind every 'Buy Now' button are a million moving parts, but smart sellers don’t leave logistics to chance—they follow the 5 P’s.

If you’re running an online store and find your team buried in backorders or shipping headaches, the 5 P’s can turn chaos into clarity. It doesn’t matter if you’re shipping sneakers or skincare. These principles keep your orders flowing and your customers coming back.

The best part? You don’t need fancy tech or unlimited cash to get started. Simple tweaks—like better planning or training your staff—outperform shiny tools if you use them right. Stick around as we break down how each “P” unlocks smoother ops and can save your business from costly mistakes.

- What Are the 5 P’s of Logistics?

- P1: Planning—Why Guesswork Costs Money

- P2: Product—Inventory’s Make-or-Break Role

- P3: Place—Warehousing and Fulfillment Hacks

- P4: People—The Human Edge in E-commerce Delivery

- P5: Processes—Making Everything Work Together

What Are the 5 P’s of Logistics?

When people talk about the 5 P’s of logistics in e-commerce logistics, they're not just using buzzwords. These are real frameworks that the best online retailers use to keep their operations running smoothly. Here's how it breaks down:

- Planning: Mapping out every step, so you don't get blindsided by demand spikes or inventory shortages. This is your game plan for everything—from what gets restocked to how you handle shipping during flash sales.

- Product: Having the right inventory, knowing exactly what's sitting in your warehouse, and tracking it like a hawk. Don't just stock everything and hope for the best—smart product management means tighter margins and happier customers.

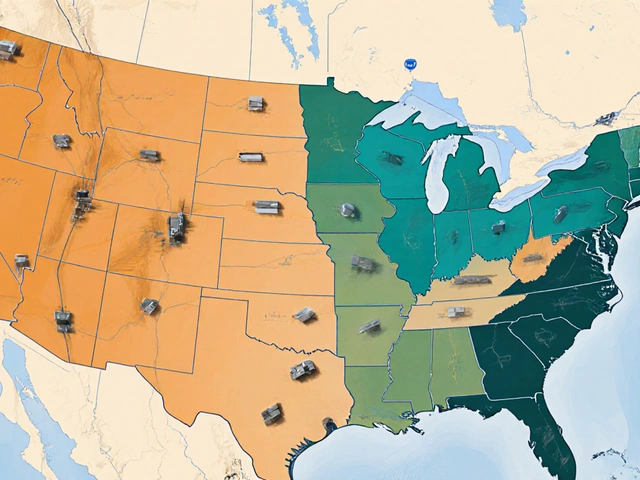

- Place: Where your goods are stored and how quickly they can get to customers. Are your warehouses in the right spots? Is your fulfillment partner slowing you down? Location choices cut down on costs and delivery times.

- People: Even the best software can’t replace a sharp, well-trained team. Your warehouse crew, drivers, and customer service reps all play a part in making sure orders get picked, packed, and shipped right.

- Processes: All the steps, routines, and checklists that keep your deliveries on track. Automation is great, but sloppy processes wipe out all those supposed efficiency gains.

Each “P” is a safety net; if you miss just one, things can go sideways fast. For example, a 2023 industry survey showed that almost 40% of recent shipping delays were tied to poor planning, not external events like weather or carrier mistakes. Ouch.

If you want your e-commerce logistics setup to compete with the big dogs, keep these five moving parts in sync. It’s not glamorous, but it’s what turns first-time buyers into loyal fans.

P1: Planning—Why Guesswork Costs Money

There’s no sugarcoating it: winging it in e-commerce logistics kills profits, breaks trust, and creates angry customers. Solid planning is what separates a thriving online store from one that’s always apologizing for delays. Shoppers today expect same-day or next-day delivery almost everywhere. According to Shopify’s 2023 report, nearly 62% of abandoned carts were linked to long or uncertain delivery windows. The lesson? If you’re not planning every step in the supply chain, you’re just burning money.

Planning isn’t just about making a to-do list. It’s about predicting demand, managing suppliers, and getting your delivery times right—all before someone hits “Buy.” Smart stores use simple tools like:

- Forecasting spreadsheets tied to sales data

- Inventory alerts that warn you before stockouts hit

- Supplier calendars—so you know when to reorder, not just when it’s too late

One quick win: review your last holiday season’s sales. Most shipping snags happen the same way every year. Set reminders ahead of those dates and bump up inventory and staffing before the rush. Even the giants like Amazon run test sales outside Black Friday to prep for real traffic—copy this idea and you’ll catch slowdowns before they sink you.

If you’re working with a tight budget, free project management tools like Trello or Google Sheets can tackle most planning headaches. The point is, stop guessing. Every missed delivery, every out-of-stock email, costs you more than just one sale—it eats away at your reputation. Upgrade your planning, and the rest of your e-commerce logistics game gets easier by default.

P2: Product—Inventory’s Make-or-Break Role

Here’s the thing—if you don’t have the right products in stock, it messes up everything else in e-commerce logistics. Nothing frustrates customers more than clicking “order” just to get a “backordered” notification later. Worse, too much inventory drains your cash and fills up your warehouse with stuff that might never sell.

Big online retailers like Amazon live and die by their inventory accuracy. According to a 2024 survey by Ware2Go, 43% of small e-commerce businesses lost sales because products advertised as “in stock” were actually sold out. If you sell on marketplaces, this can even get your listings suspended.

So, how do you avoid inventory chaos? It really comes down to three things:

- Real-time inventory tracking: Use software (even spreadsheets for starters) that updates your numbers whenever you make a sale. Manual tracking is risky and slow.

- Forecasting demand: Don’t just guess. Look at last year’s sales, seasonality, and even social media trends. This helps you order the right amount—and not overstock on stuff that won’t move.

- Matching sales with storage: Make sure your most popular products are easy to grab in your warehouse or fulfillment center. Don’t bury bestsellers behind slow movers.

Many brands now use “just-in-time” inventory, meaning they order products only when they know there’s demand. It saves money but needs tight control and reliable suppliers. If you’re just starting out, strike a balance—you don’t want shelves empty, but massive piles of unsold stock won’t help either.

Here’s a quick look at the impact of inventory mistakes in online stores:

| Inventory Problem | Customer Impact | Business Cost |

|---|---|---|

| Out-of-stock | Frustration, lost trust | Missed sales, negative reviews |

| Overstock | No direct impact | Tied-up money, storage fees |

| Inaccurate tracking | Order errors, delays | Extra handling, refunds |

Dial in your supply chain by staying on top of what’s coming in, what’s going out, and what customers actually want. Inventory isn’t just counting boxes—it’s making sure every product supports your bigger logistics strategy.

P3: Place—Warehousing and Fulfillment Hacks

Here’s where e-commerce logistics gets real—your “Place” isn’t just about a building full of boxes. It’s about how smart your setup is, how quick you can pick, pack, and ship, and whether you’re losing money with every square meter you rent. Around 30% of fulfillment costs come down to warehousing, so even simple changes can seriously boost your bottom line.

Let’s get practical. If you run a smaller shop, don’t drown in rent just because you want control. Third-party logistics (3PLs) now offer shorter contracts and let you scale up (or down) in busy seasons. Amazon FBA, ShipBob, and Flexport are popular 3PL options—look for providers with a strong reputation for accuracy and speed, especially if your brand lives or dies by fast delivery.

Now, what about those boxes getting lost, damaged, or overlooked? Around 8% of e-commerce returns are caused by picking errors made in the warehouse. To cut this number down, use:

- Barcode scanners for every product and shelf

- Clear bin labeling and storage maps—no guessing games

- Batch processing, so you pick multiple orders in one trip

You're not just fighting chaos—you’re speeding up fulfillment. Also, think location. If you ship nationwide, consider splitting inventory between warehouses closer to your biggest customer clusters. Fast deliveries mean happy reviews and fewer complaints. According to Shippo’s 2024 survey, 62% of shoppers say quick shipping is their number one factor for repeat orders.

If your volume is spiking, look for warehouse management systems (WMS) that sync with your online store. They track stock in real time, so you don’t oversell and disappoint customers. Some platforms even flag slow-moving products so you can run flash sales and free up shelf space.

| Fulfillment Factor | Typical Cost Impact | Pro Tip |

|---|---|---|

| Warehousing | 15-30% of logistics spend | Use 3PLs for flexibility |

| Packing Errors | 8% of returns | Scanner and map everything |

| Shipping Speed | Direct link to repeat business | Stock up near your main customers |

Don’t let “Place” drag you down. Smart moves here turn headaches into profit and buy you freedom to grow, not just store stuff.

P4: People—The Human Edge in E-commerce Delivery

Even with the smartest software and high-tech robots, your team—your people—make or break your e-commerce logistics. No app on earth can replace a sharp warehouse worker who notices a damaged box, or a customer service rep who turns a shipping mistake into a loyal fan. Good people decisions are your secret weapon for fewer returns, happier shoppers, and smoother days.

Training is non-negotiable. Companies who run solid onboarding see almost 30% fewer order errors in the first six months. That’s because every picker, packer, or support agent understands the product, the process, and what “done right” looks like. If you think training costs too much, wait until you’re refunding dozens of orders because of simple human goofs.

Motivation matters, too. Studies from the logistics world show engaged team members handle up to 50% more shipments per hour than those just punching the clock. People like being recognized—so something as small as an ‘Order Accuracy Star’ board or a $10 lunch voucher for top performers can seriously boost your numbers.

Here’s where real-world leadership comes in:

- Listen to your team’s bottleneck complaints. They catch slowdowns before any dashboard does.

- Keep schedules flexible, especially during peak sales or promo times. Burnt-out pickers make mistakes.

- Mix up routine with creative training days—let new hires learn from top performers, not just printed manuals.

Many e-commerce shops forget about the customer service crew. Fast, honest replies fix most delivery problems before they explode into one-star reviews. A friendly call after a delayed shipment does more than any automated apology email.

And don’t ignore health and safety. Companies that cut down workplace injuries often see a boost in daily shipments—less drama means more focus. Even simple stuff like standing mats, water breaks, and clear aisles pays off.

| People Factor | Average Impact (per month) |

|---|---|

| Extra Training | ↓20% Fewer Mis-Shipments |

| Employee Recognition | ↑15% Faster Packing Rates |

| Proactive Customer Care | ↓30% Customer Complaints |

The bottom line? Treat your team right, and your delivery reputation skyrockets. Even the best tech can’t compete with people who actually care if the order gets there on time and in one piece.

P5: Processes—Making Everything Work Together

You can have the best products, a warehouse stocked to the rafters, and a hungry customer base, but if your processes are all over the place, you’re basically lighting money on fire. In e-commerce logistics, streamlined processes are what tie your whole operation together. When you get your processes right, your team works smarter, returns drop, and your delivery times actually match what you promise online.

Let’s get real—most of the mistakes in e-commerce happen not because people don’t care, but because step-by-step instructions are missing or nobody sticks to them. A solid process means everyone knows what to do and when.

- Order Picking: Stick to clear picking paths in your warehouse, and use barcode scanners to cut down on errors. Amazon’s warehouses use algorithms to design the shortest picking routes—no surprise they’re quick.

- Packing: Standardize how you pack items. Set up a packing checklist: include slip, check product, place protection, seal. Less room for missed items or damage.

- Shipping: Use software that compares carriers and rates in real time. That way, you always know which company can do the job right (and cheapest) today—not two months ago.

- Returns: Build an easy system for returns. Transparency keeps customers calm and loyal, even when things go wrong. Plus, you can track frequent issues and fix them fast.

Here’s something wild: a 2023 survey by Statista found that 56% of abandoned online carts come from complicated shipping processes or unclear delivery timelines. That’s lost revenue you could fix with a clearer process.

| Process Step | Best Practice |

|---|---|

| Picking | Use real-time barcode scanners & route optimization |

| Packing | Checklist for every parcel |

| Shipping | Auto-rate comparison tools |

| Returns | User-friendly self-service returns platform |

If you haven’t mapped out your processes lately, grab a whiteboard and walk through the exact steps from order to delivery. Find out where staff waste time or where mistakes pile up. Even tiny changes—like reorganizing your packing area—can shave minutes off each order. In the world of e-commerce logistics, every minute and every click matters.